Finally, new kinematics for 3D printers is here!

We are different!

We like to build and combine things! We like hybrids!

Similar to CoreXY concept, but in another dimension....

What if z-hop takes zero time?

Faster than Kossel Deltas... Accurate as Prusa... Big as CR-10... Robust as Mendel... Silent as butterfly...

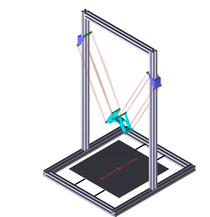

Our tools are getting cheaper, faster and more accurate. CoreXZ parallel arms motion platform is one evolutionary step in that direction.

CoreXZ provides a fundamental building block for many computerized fabrication tools - 3D printers, CNC routers, assembly lines - in a simple,

adaptable and scalable format.

CoreXZ is a technique, not an implementation.

We sketch the concept and give a few examples as a platform that enables you to build new tools that are as unique as your ideas.

Fast. Faster. Fastest.

We believe in speed. CoreXZ's parallel arms kinematics allows to keep motors outside of the printing area. This means that all your motors,

will stay cool even if you print high temperature materials (like ABS, PC) in an enclosed environment. 2 motors are engaged in toolhead movements.

This allows rapid accelerations, better positioning and great repeatability.

Universal.

CoreXZ can be implemented in a wide variety of mechanisms and tools, assembly lines, 3D printers, CNC routers. It's a new platform with unlimited possibilities.

Just unleash your imagination!

Scalable.

Current design is meant to match most popular printing platform size - 12".

Larger scaling is easy and we are planning to implement it in future versions.